Insertion loss

Determine the insertion loss of a virtual prototype with the CEVAA to accelerate and secure the development of the deck penetration.

Insertion loss (IL)

The sound insulation of the engine compartment is an important factor in the NVH comfort of vehicles. The bulkhead is the main channel for transferring noise from the engine to the passenger compartment, whether for a combustion engine or an electric engine.

For this particular reason, the acoustic specifications of car manufacturers for the apron are increasingly restrictive, in particular for the crossings of the various equipment and components (cable, steering column, brake booster, gearbox control, etc.) .

Insertion loss (IL) is one of the main indicators for determining the acoustic performance of deck penetrations. The IL is the difference in sound pressure level between two configurations: a reference configuration and a configuration with the tested sample.

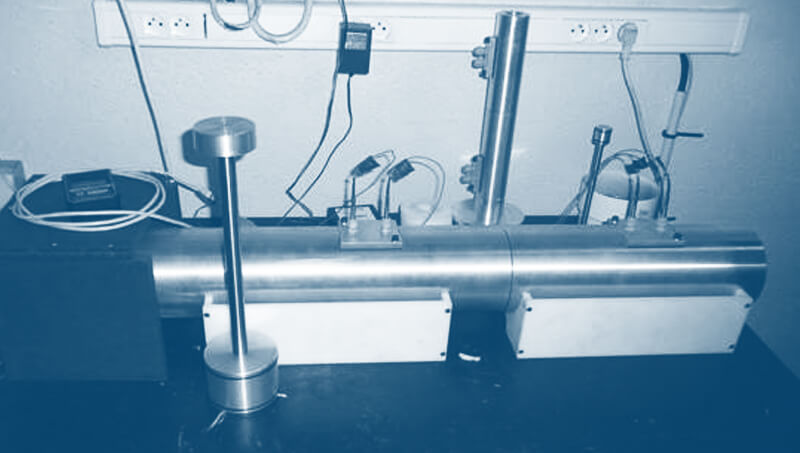

IL can be measured using the small cabin. This is a specific bench with a source cavity and a receiver cavity. The parts tested being at the interface of these two cavities.

Insertion loss calculation

P1 and p2 are respectively the transmitted pressure measured in the cavity when receiving the first configuration and the second configuration. P0 is the reference pressure and it is equal to 20 μPa. IL is always expressed in dB.

The higher the IL, the better the acoustic performance of the tested sample.

Benefits of CEVAA expertise

Deck penetration suppliers often have to test several prototypes, made from combinations of different geometric configurations and/or different materials. This can quickly lead to prohibitive development times and costs to meet the manufacturer’s performance requirements.

One way to speed up and secure the development of a deck penetration is to use the determination of the insertion loss of a virtual prototype.

For this, the CEVAA developed a finite element model of the small cabin and correlated it with experimental measurements of the insertion loss for different types of deck penetrations.

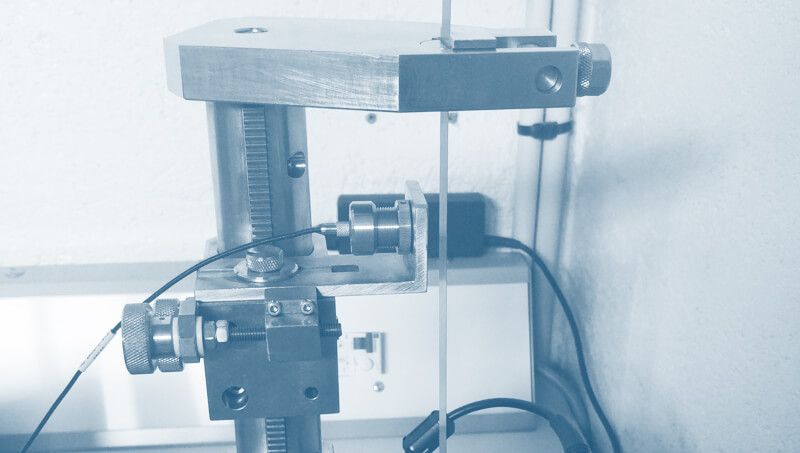

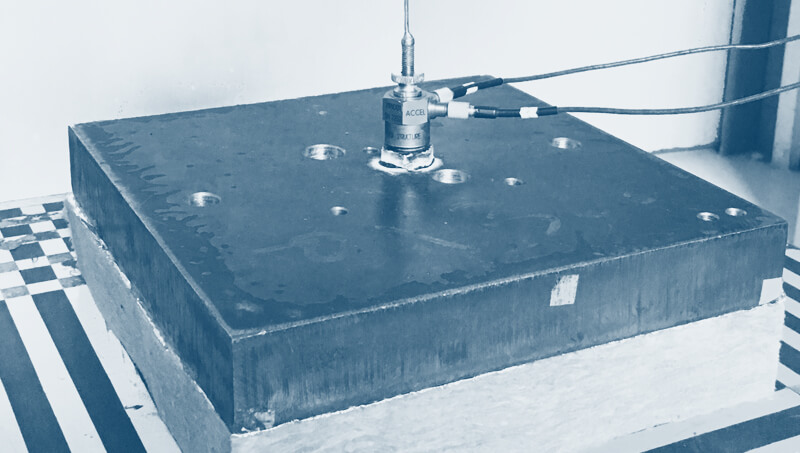

Materials characterization benches

For more information, contact us to discuss technically on your needs!