Poisson’s ratio characterization bench

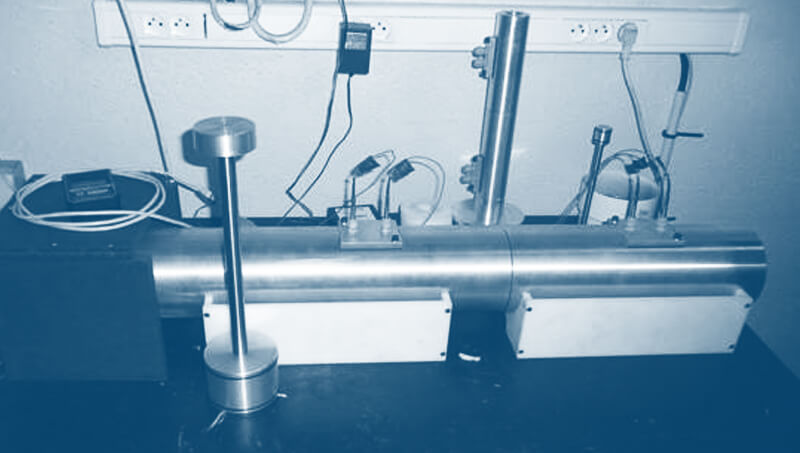

The CEVAA has set up a new testing bench to carry out the dynamic characterization of the Poisson’s ratio of acoustic materials.

The bench is also able to provide a representation of the behavior of the material in its environment during mechanical vibration and/or acoustic problems.

This new service offered by the CEVAA makes it possible to feed the calculation models with more precise material parameters. In addition, it makes it possible to make dynamic simulations more representative of the real phenomenon.

It is thus possible to predict the vibro-acoustic behavior of systems incorporating viscoelastic polymers (or other materials).

The knowledge of the Poisson’s ratio of our materials, in particular those based on viscoelastic polymers, remains to this day very fragmented. Our collaboration with CEVAA has enabled us to develop an experimental device without contact leading to a much more precise estimation of this parameter.

Its application has been proven on different ranges of materials, allowing a better understanding of the limits of the bench. In the medium term, this type of approach will be valuable for us to predict the vibro-acoustic behavior of systems incorporating this type of material.

Technical characteristics

Experimental setup

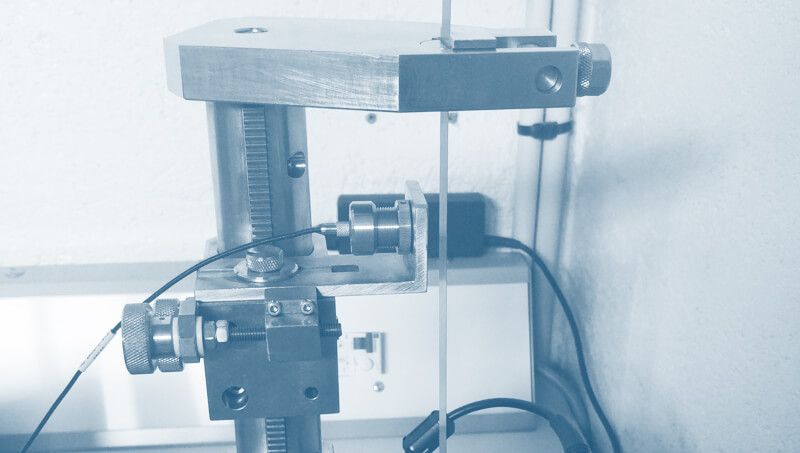

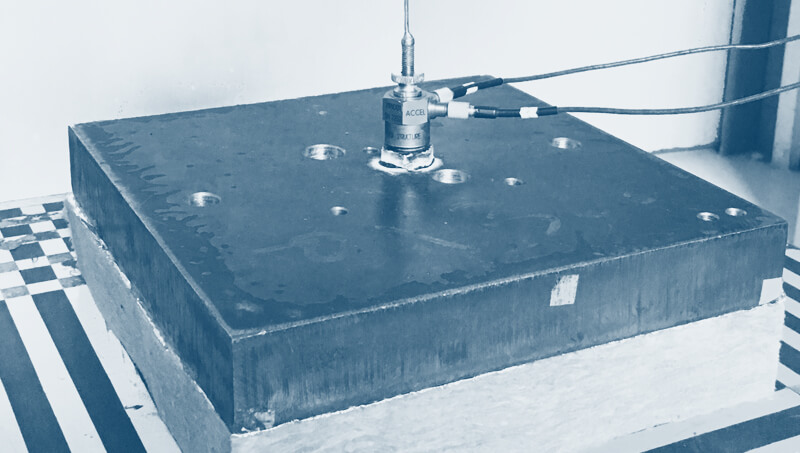

The material to be tested is prestressed between two plates, the lower plate being excited by a vibrating pot. An accelerometer recovers the vertical displacement on the lower plate while a laser vibrometer measures the lateral displacement on the surface of the sample. An abacus is constructed based on simulation. Several finite element calculations are carried out by reproducing the experiment.

Area of validity

from 20Hz to 90Hz

Types of materials

viscoelastics, plastics, EPDM, etc.

Materials characterization benches

For more information, contact our teams!