Dynamic force measurement

The CEVAA carries out dynamic force measurement. We have the equipment and the skills to carry out the characterization of triaxial and multipoint blocking forces of your mechanical systems.

Motors and mechanical systems

Most of the active systems that are part of our daily lives, both personal and professional, entrust the heart of their motricity to motors.

These, via various kinematic chain elements, transmit their energy to other mechanical elements making it possible to perform the primary function of the system. Finally, so that unity is ensured between these various elements, they are made united via a reception structure.

Vacuum cleaners, coffee machines, trains, electrically assisted bicycles, industrial machines (machine tools, conveyors, packaging machines, etc.) are all examples of a non-exhaustive list of systems responding to this style of product architecture.

Another example that speaks to everyone is the automotive industry. Indeed, a car is composed of a heat engine connected to a gearbox, itself in connection with the transmissions/wheels assembly allowing to ensure its function of movement on the road. Finally, these mechanical subsystems are made integral by means of a box to which they are connected.

The body, which can be described as a receiving component, intrinsically comprises Eigen Frequencies (depending on its geometry and its material(s)) with which it resonates.

Acoustic expertise of CEVAA

The motors are, for their part, vibration sources of very generally substantial amplitudes.

Thus, in the event that one or more motor excitation frequencies are found to coincide with one or more resonance frequencies of the passive component, high vibro-acoustic levels could emerge and cause acoustic discomfort for users.

It is therefore advisable to avoid these sources/resonance frequency coincidences by determining, upstream of the V cycle, the frequencies and amplitudes of excitation of the motorized substructures.

Blocked forces characterization

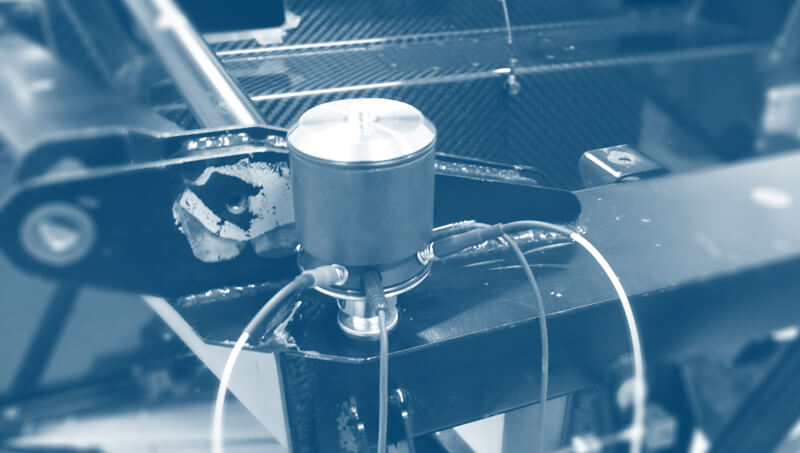

The most commonly used means is the characterization of blocked forces. It consists in placing the subsystem on a neutral bench from a vibratory point of view (no resonance in the frequency range of study) and equipped with force sensors.

The use of the Solidworks mechanical design software as well as the LMS TestLab vibro-acoustic acquisition and post-processing software allows you to be supported throughout this characterization process: from the design of a bench to the measurement of efforts.

For more information, contact our teams!