Vibration analysis

CEVAA provides vibration analysis and expertise to identify, understand and resolve vibration-related problems in various areas.

Vibration analysis by expert engineers

CEVAA supports manufacturers in vibration diagnosis and the implementation of solutions to reduce vibrations and improve system performance. Our design office provides expertise and advice in resolving complex problems.

Thus, our team of engineers and technicians specialized in vibration analysis have a methodical and rigorous approach. We guarantee reliable and precise analysis of vibration phenomena with cutting-edge technologies and efficient software.

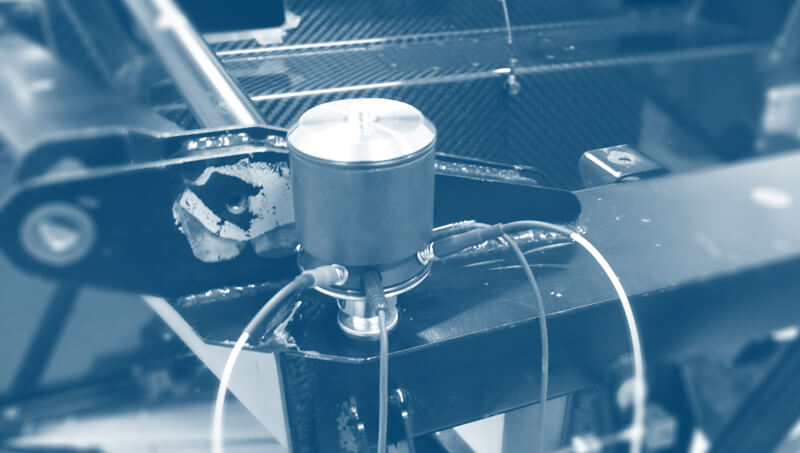

- Vibration measurement: on-site data acquisition using high-performance sensors and measuring instruments.

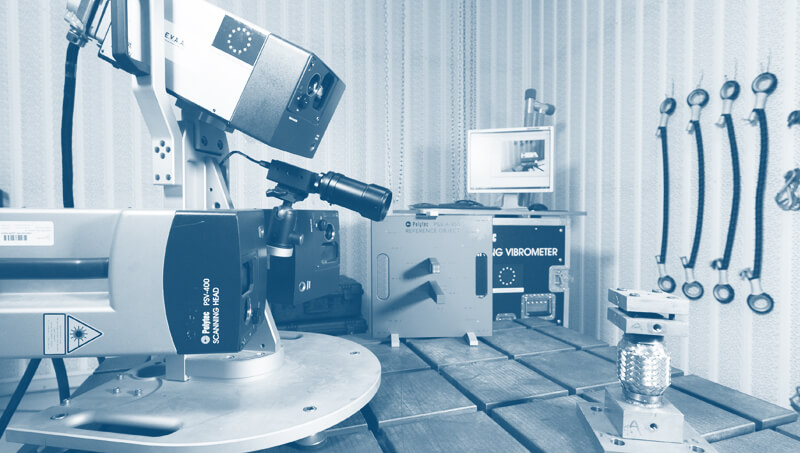

- Modal analysis: study of the modal properties of systems in the frequency domain in order to predict the in-service vibration behavior of a mechanical structure under artificial or real stress.

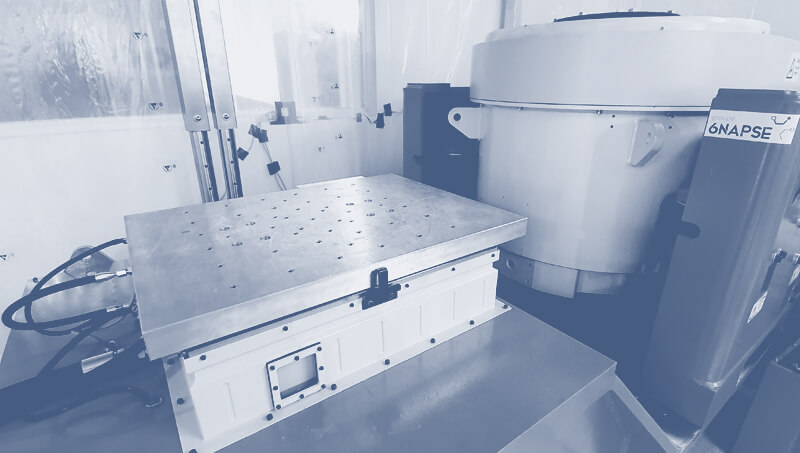

- Endurance testing on shakers: reproduction of accelerated vibration aging in a test center

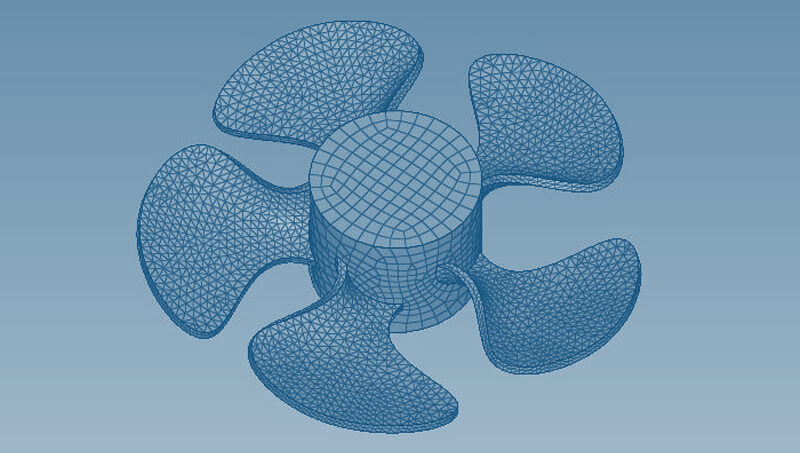

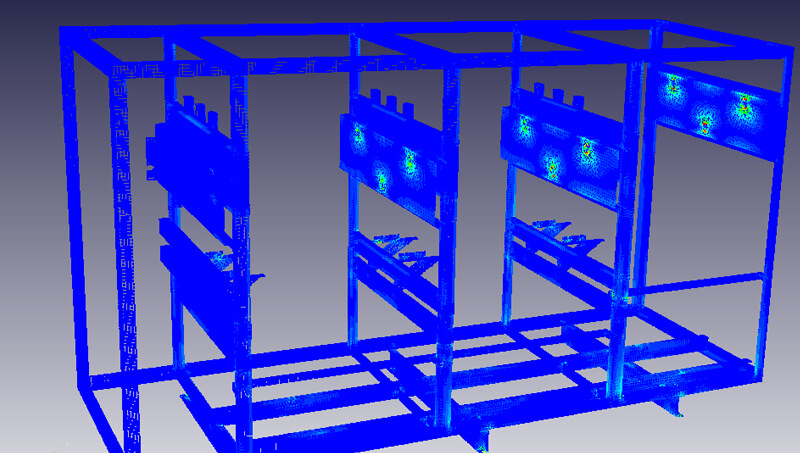

- Numerical vibration modeling: simulation of the vibration behavior of the structure or system studied.

- Diagnosis and solutions: determination of the root causes of vibrations and proposal of corrective solutions.

Vibration measurements and testing

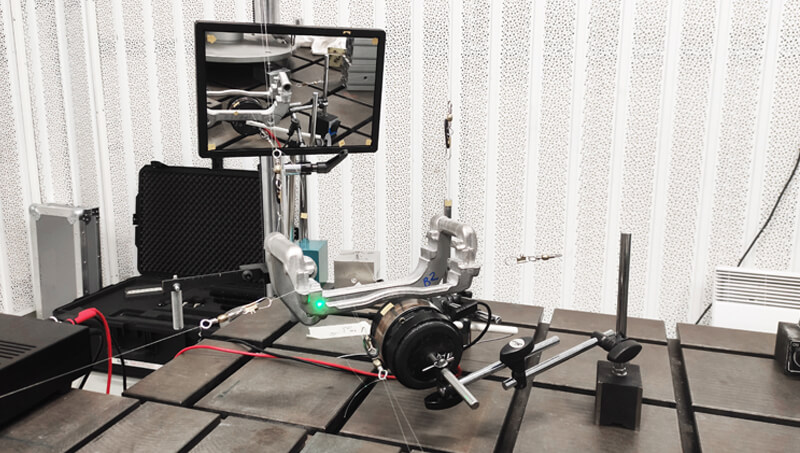

For vibration analysis, we have equipment such as electrodynamic shakers and structural measurement means (accelerometers).

Furthermore, CEVAA also carries out non-contact measurements and vibration characterizations using 3D scanning laser vibrometry. The advantages are the ultra-precise measurement undisturbed by the mass of the accelerometer sensors in the case of small systems to be studied or the application of a much denser mesh than with accelerometers. Operational or modal shapes make it possible to visualize compliance with specifications or to visualize defects or possible improvement of the system to be studied. In addition to this, these data measured by vibrometry and accelerometers can be used for digital model adjustment. We can also import a digital mesh to aim for an optimized calculation/test correlation.

Finally, CEVAA supports you in optimizing comfort and vibration reliability as well as in verifying compliance with the tolerance thresholds imposed by the standards. Vibration analysis by our design office provides valuable expertise for controlling vibrations and ensuring the sustainability of your installations.

Contact us for an vibration analysis of your project and obtain tailor-made solutions.

Applications

- Transport / mobility: control of vibration comfort inside the vehicle, search for vibration pathways, design iteration on automobile parts, calculation of the mechanical strength of an automobile fan, vibration analyzes on systems (rail vehicles, automobiles, etc. electric bike, etc.)

- Electric motor: vibration simulation to reduce noise induced by electric motors

- Aeronautics and space: validation of system reliability, help in diagnosing the appearance of vibration on a rocket engine

- Defense and security: experimental modal analysis (by accelerometer and 3D laser vibrometry), on-board vibration measurements in operational conditions, determination of a vibration problem on a component presenting a defect in operational conditions, analysis and prediction of failure on a rotating radar

- Naval: measurement and analysis of noise and vibrations of machinery, particularly for cabin comfort

- Household appliances: diagnosis or comparison of vibration problems on household appliances, vibration measurement on a vacuum cleaner to reduce noise and vibrations, reduction of vibrations on a bean-to-cup coffee machine

- Energy: seismic calculation of nuclear installations and new energies

- Industry: vibration control of industrial production machines (e.g.: rotating machines, pumps, fans, compressors, turbines) according to safety standards

CEVAA experts

- Significant experience in vibration phenomena (industrial, automotive, aeronautics, aerospace, etc.)

- Creation of a complete validation plan (management of all tests of a standard)

- Experimental research

- Vibration simulation

OUR TECHNICAL MEANS

For more information, contact our teams!