Acoustic measurement, noise measurement and silent design

The CEVAA offers its customers support on the “acoustic expertise” aspect in the different phases of a product’s life. We carry out acoustic measurements.

From diagnosis, to measurement or simulation via our acoustic test resources (semi-anechoic chamber, small cabin, oberst method, code_aster, etc.), our goal is to help you design silent products.

Design silent products

Today, noise is recognized as an important environmental factor that directly influences stress, fatigue and the health of users. Household appliance manufacturers, car manufacturers and even the building sector have understood it for a long time, as shown by the technical evolution of products over several decades. The consumer would not accept a rollback with an increase in noise and therefore a deterioration in his quality of life.

Noise is also a criterion of perceived quality (acoustic comfort) and an indicator of design or manufacturing problems. The noisier a system is, the more it reveals a malfunction. An example is that of a problem with the balancing of a rotating system (example: fan, turbine or shaft on bearings) which, when it appears, is accompanied by an increase in the noise level. Another example is that of air noise inside a car coming from poor acoustic sealing at door seals or window seals.

Whatever the problem, it is necessary to quantify the noise level and its frequencies of appearance, through acoustic measurements or digital simulations.

Acoustic expertise of CEVAA

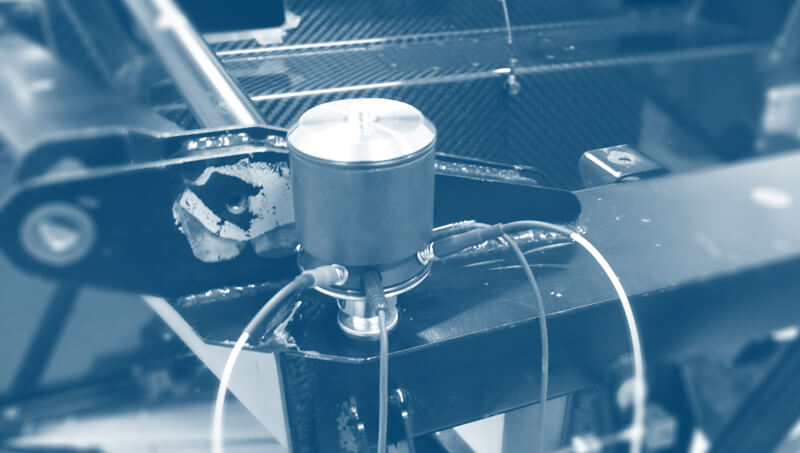

For this, the CEVAA teams mobilize all their skills and appropriate equipment, whether in terms of microphones, acoustic sources (LF, MF/HF), acquisition and post-processing software or, vibro-acoustic simulation software.

The CEVAA offers its customers support on the “Acoustic Expertise” component in the different phases of a product’s life:

- Pre-project: Drafting of specifications, acoustic pre-study;

- Development: Support for product design with requirements in terms of acoustic performance, characterization of input data necessary for digital simulation (material properties, excitation profile, etc.), vibro-acoustic simulation of a prototype virtual and design iteration;

- Validation plan: Acoustic measurements on a physical prototype, analysis of transfer paths, characterization of noise sources, diagnosis, modeling of corrective solutions (in absorption, insulation and/or damping), verification of the achievement of the requirements defined in the specifications loads.

- Production: End of line measurements for quality control, deployment of in-situ solutions.

Our expertise in acoustic phenomena leads us to intervene in all industrial sectors. Our teams work in compliance with measurement standards and customer test procedures, but also by developing innovative characterization and simulation methodologies.

Key skills

- Knowledge of acoustic phenomena (industrial, automotive, aeronautics, aerospace, etc.)

- Acoustic comfort

- Silent design development support

- Development of innovative characterization methods

- Experimental research and acoustic simulation

Applications

- Support in the upstream development phase (NVH) complete vehicle or systems.

- Acoustic diagnosis and problem solving

- Identification of noise sources by analysis of transfer paths or listening (Squeak and Rattle study)

- Analysis of vibrational and acoustic properties of materials

- Accompaniment of customers in compliance with specifications and standards in force

Objectives

Identify the sources of noise, propose solutions to enable the customer to reach a level of requirement governed by a standard, a specification or propose a solution to an inconvenience.

OUR TECHNICAL MEANS

For more information, contact our teams!