Squeak and Rattle : test bench

Two means are available at CEVAA:

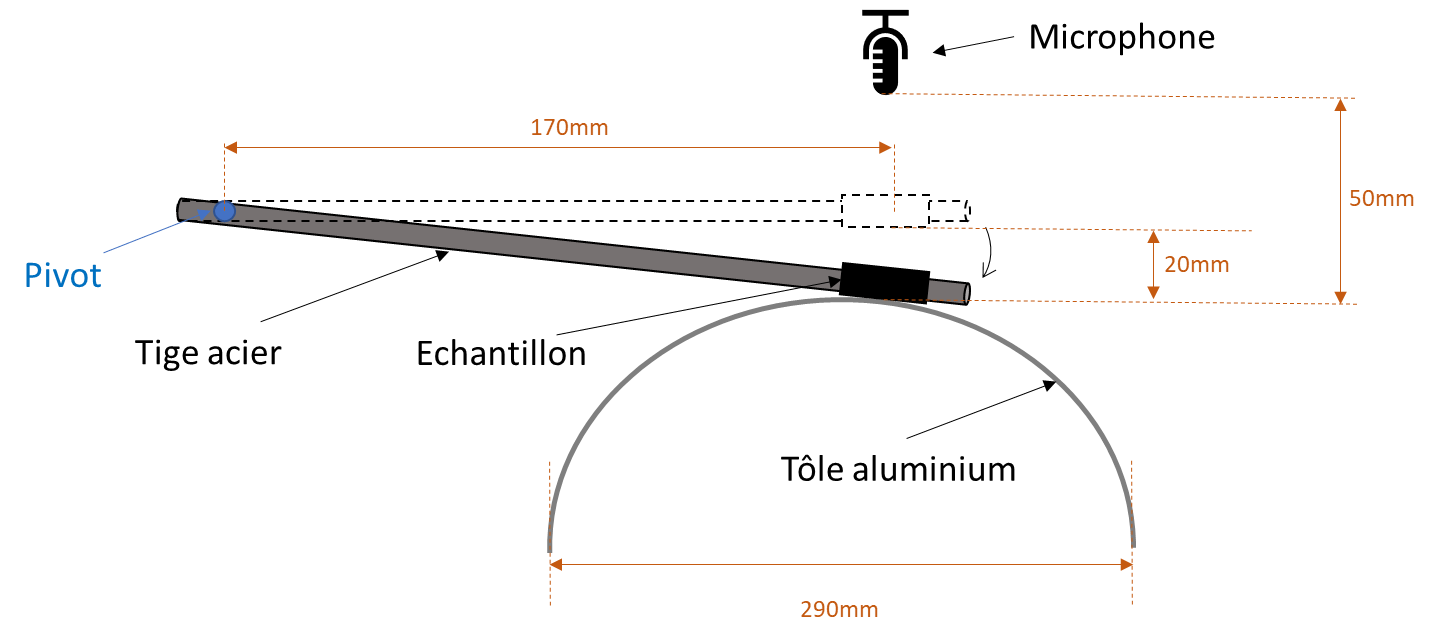

Method 1 : impact noises

A steel rod is dropped vertically on a bell-shaped aluminum plate. The noise measurements are carried out without samples, then with a sample on the rod at the level of the impact zone. The whole is placed in a quiet environment (semi-anechoic chamber or squeak and rattle chamber).

The average attenuation level generated by the sample (Natt in dB(A)) is the difference between the two calculated levels:

Natt = Nsam – Nrod

Method 2

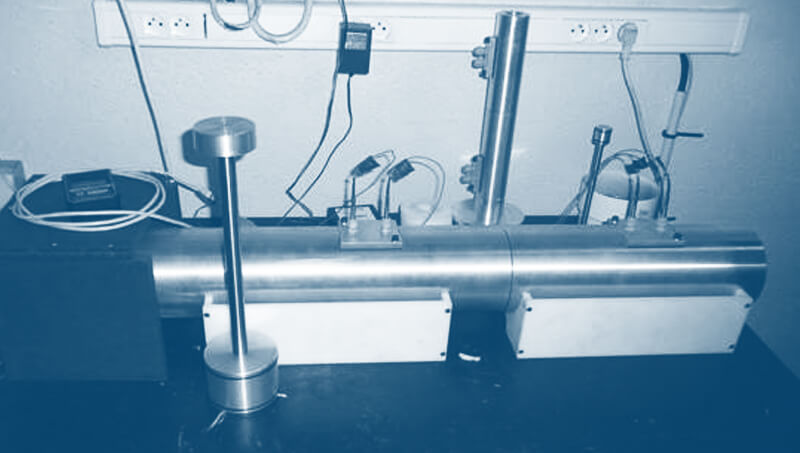

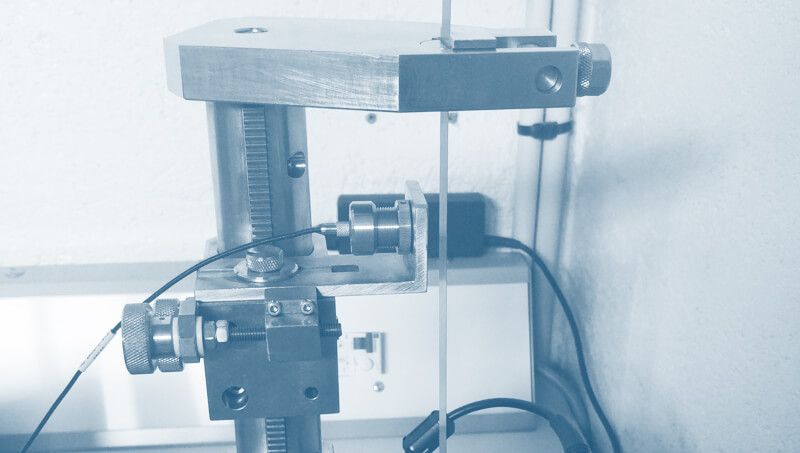

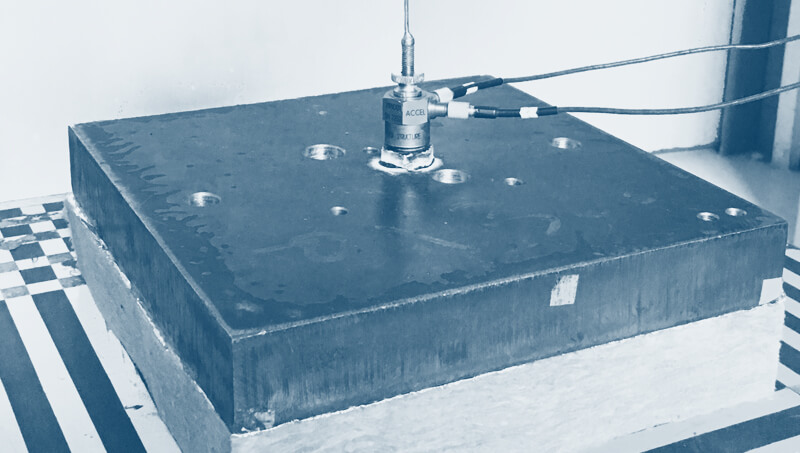

Claps noise

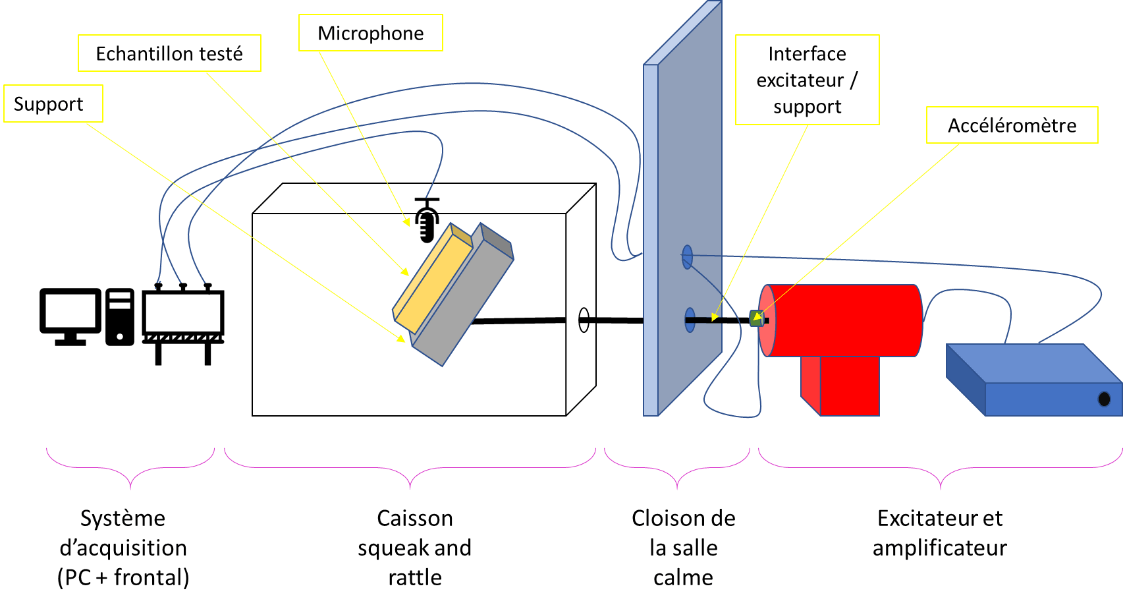

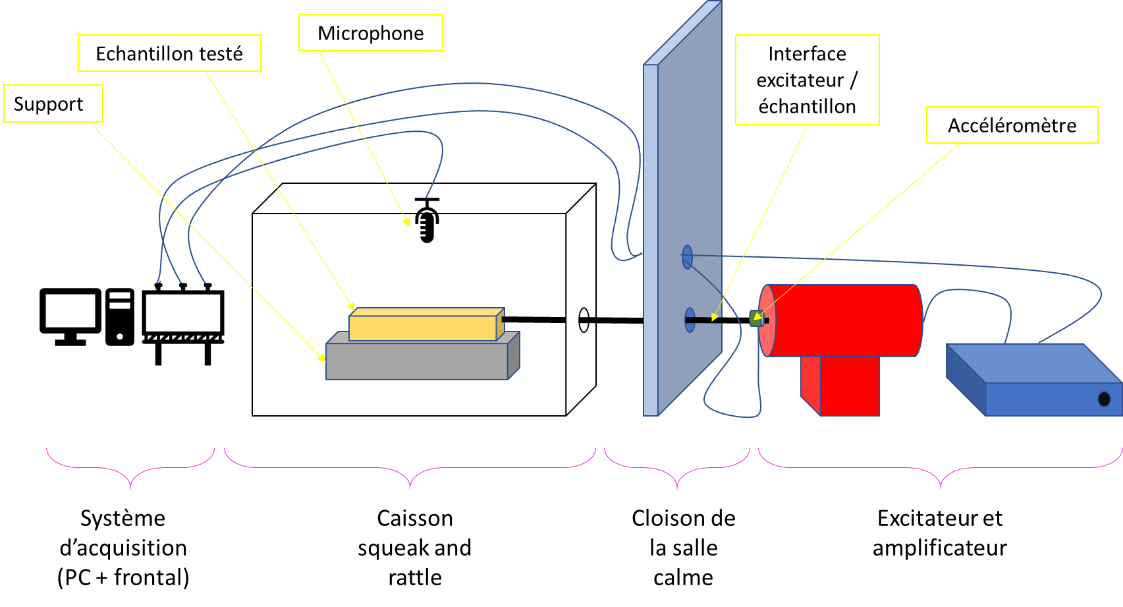

The element to be tested (cable or wire harness) is placed on a steel plate excited at 9 Hz (displacement of +/- 5 mm). A microphone is placed 150 mm from the steel plate.

Frictions noise

The element to be tested (cable or bundle of cables) is placed on a steel plate, it is excited according to the same profile used for the claping noise.

Measurements / calculations made

The average attenuation level generated by the sample (Natt in dB(A)) is the difference between the two calculated levels:

Natt = Nsample – Nrod

Examples of completed projects

Innovative materials characterization

Reference procedure

- Standard SAE J2192 revised 2016-06 “Recommended testing methods for physical protection of wiring harnesses”

- Standard Renault 16-00-001 -L dated 03/31/2017 “Protective Tape for harness”

- BMW Standard GS 95008—3 revised 2005-10 “Adhesive tapes for wiring harnesses in motor vehicles”

Materials characterization benches

For more information, contact our teams!