Dynamic mechanical analysis (DMA)

CEVAA carries out and supports manufacturers in dynamic mechanical analysis (DMA).

In order to meet the need for characterization of materials, particularly polymers, CEVAA from 6NAPSE group supports manufacturers in dynamic mechanical analysis (DMA).

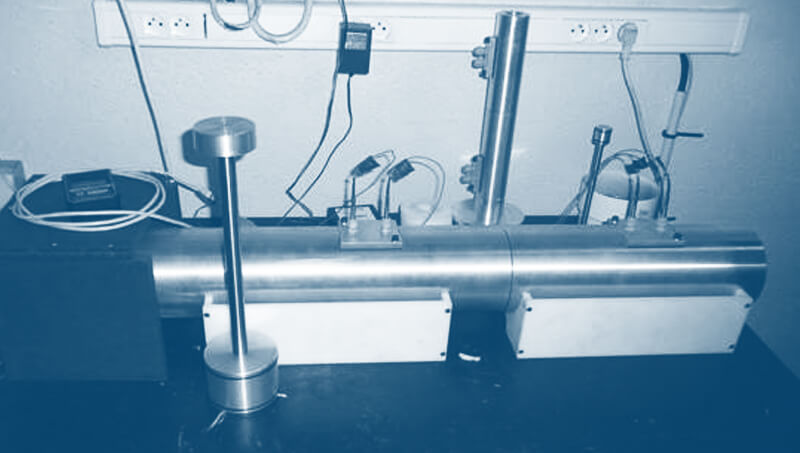

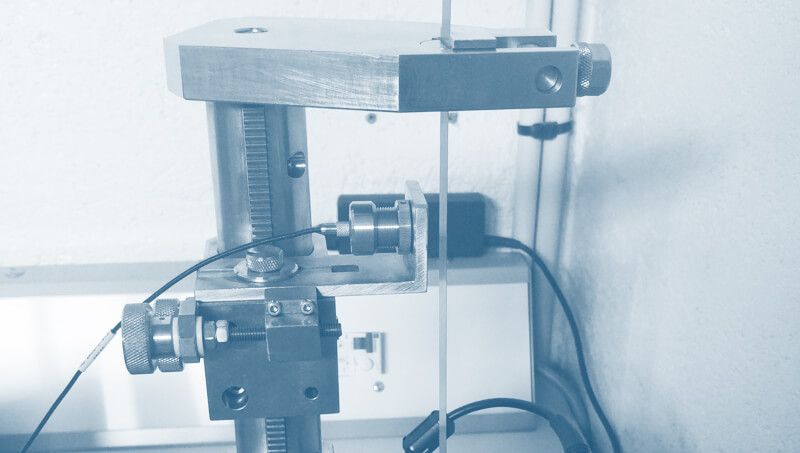

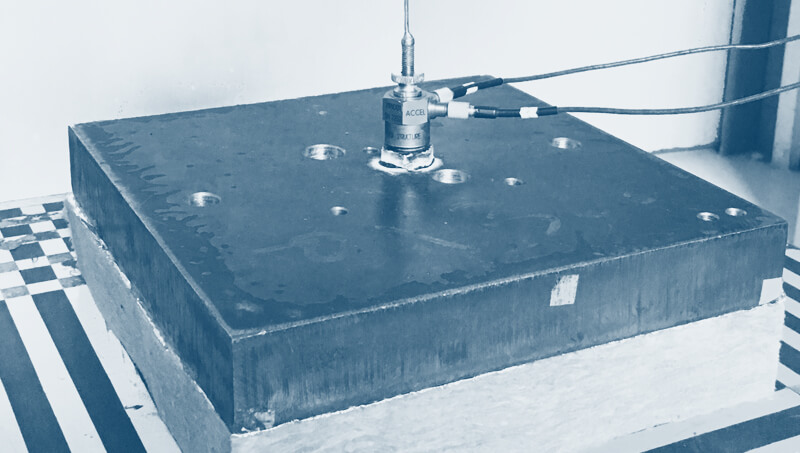

Our equipment makes it possible to obtain the mechanical properties of the material. The plate, beam or cylinder type samples have reduced dimensions of a few tens of millimeters. CEVAA offers a great versatility of stress modes.

- Moduli: complex, storage, loss, shear

- Stress modes: traction, compression, shear on embedded sample and bending on “free-free” sample

Following the results of the DMA, it is possible to go further in the definition of material properties such as the Poisson’s ratio.

DMA advantages

From the measurement of the intrinsic properties, the moduli, the loss factor and the glass transition temperature, we can:

- Establish relationships between the structure, the morphology of materials and the performance required for the end use.

- Determine the field of use in temperature, frequency and rate of deformation

- Predict the long-term or extended-frequency behavior of materials using WLF or Arrhenius laws.

Technical characteristics

Mechanical Parameters

- Young’s modulus (traction, compression or bending)

- Shear modulus

- Loss factor (damping)

- Thanks to the Young and shear modulus, we can determine the Poisson’s ratio

- Glass OR rubber transition (variation in temperature [-150; +450] °C and in frequency [0- 200] Hz)

Sample sizes

- Tensile: parallelepipedic shape sample [60x20x10mm] max / cylindrical shape sample [50x3mm] max

- Compression: parallelepipedic shape sample [60x40x40mm] max / cylindrical shape sample [60x40mm] max

- Bending: parallelepiped shaped sample [60x26x4 mm] max and minimum length of 50 mm

- Shear: Cylindrical shaped sample [20×10mm] max

Materials characterization benches

For more information, contact our teams!