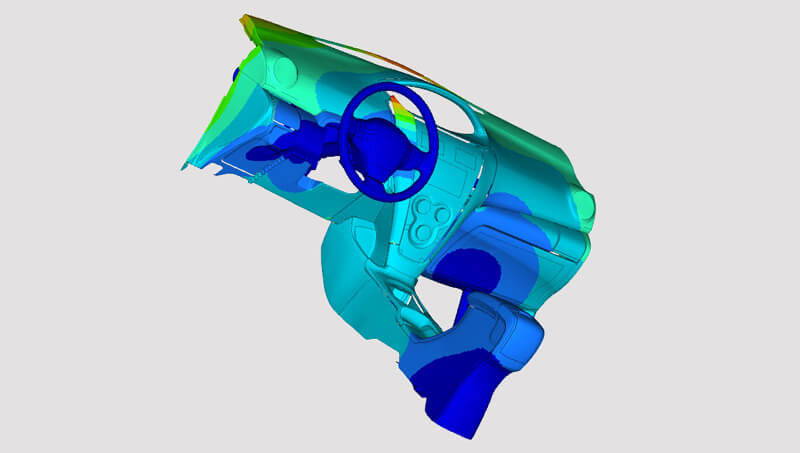

Squeak and Rattle Simulation

The CEVAA is recognized for its Squeak and Rattle simulation, tests and characterization of harshness noise.

Harshness noise

The emergence of parasitic noise is a recent problem resulting from the progress made to reduce the noise level in the passenger compartment. Crackling noises are induced by random impacts (rattle), while squeaking noises are generated by friction/sliding (squeak) between parts.

Many subsystems are concerned: door panel, door, tailgate, center pillar trim, head-up vision system, HVAC, seats, etc.

With new hybrid and electric engines and increasingly demanding consumers in terms of comfort, controlling these noise phenomena is now a major issue in terms of perceived quality.

Squeak & Rattle testing experience

With its recognized experience of experimental Squeak & Rattle tests, the CEVAA is now at the forefront of these simulation tests.

The establishment of its partnership with the company ALTAIR ENGINEERING France, the CEVAA has made the simulation of these phenomena a strong axis of the development of its modeling and calculations pole. Its engineers are now working in project mode with automotive manufacturers and suppliers.

Objectives of the simulation

Squeak & Rattle simulation allows to:

- Do derisking early in the project development cycle (good correlation calculations/tests on the identification of risk areas)

- Identify the main causes of the emission of unwanted noise and correct them

- Reduce the time spent at the end of the project to adjust the assemblies between components on the physical prototypes

Technical description

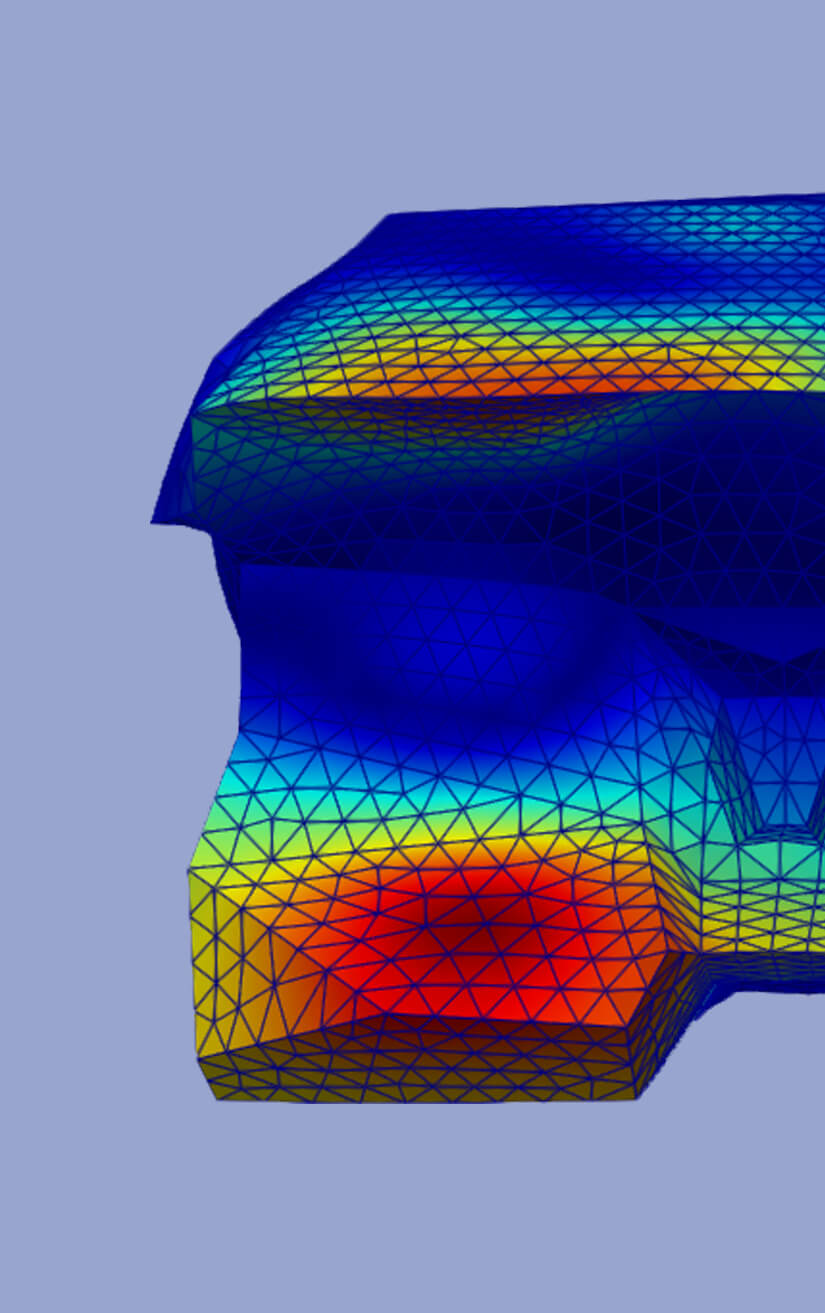

Squeak

- Relative displacement : stick-slip phenomenon

- Energy releases when µstatic > µkinetic

- 200 Hz – 10 kHz

- Shear move of 1mm enough to create squeak

Rattle

- Relative displacement : impact-induced

- Loose/overly flexible/insufficient attachment

- 200 Hz – 2 kHz

For more information, contact our teams!