Static Torsional Stiffness from Dynamic Measurements

The static torsion angle of automotive bodies is an important design parameter for measuring the overall resistance they offer to torsion.

In a permanent context of cost and development time reduction, the CEVAA has developed, in collaboration with a major automobile manufacturer, a new methodology, making it possible to determine the overall static rigidity of automobile bodies.

Traditionally, specialized testing means are used to measure torsional and static bending angles. They require expensive instrumentation, intensive resources and are destructive for test media.

Dyna2stat: a solution by CEVAA

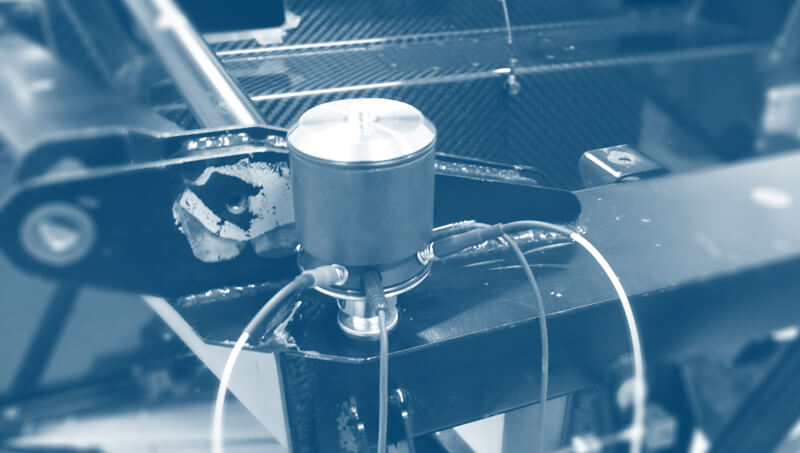

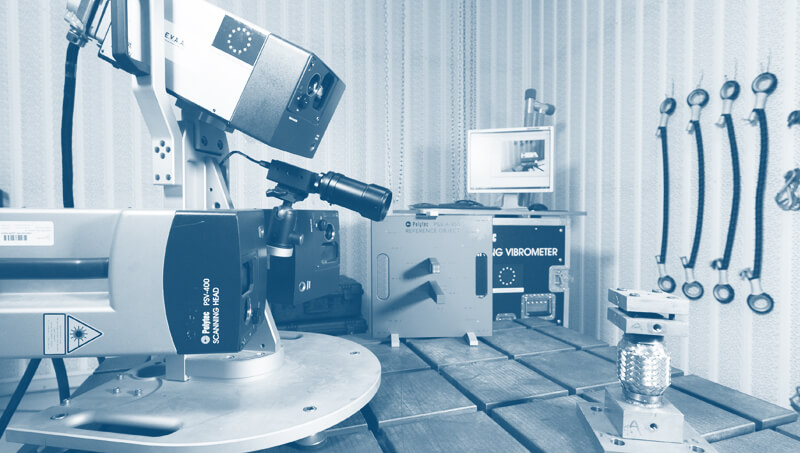

Our solution is based on the use of standard dynamic measurement equipment to determine the overall static rigidity of the body.

From the frequency response functions, measured on the structure to be characterized in free-free condition, an analysis based on the modal approach is carried out.

All of these data are then used to calculate the global stiffness function of the structure, allowing the static torsion angle to be estimated.

The theory of this bench was developed by comparing the estimate of the static torsion angle with the reference value measured on a classic torsion test bench. Over the past years, this methodology has been applied and improved on around twenty different bodies, all of which come from mass-produced vehicles.

Originally, this characterization technique was developed for the automotive sector. It is nevertheless applicable to other sectors of activity, such as aeronautics or rail, and to all sizes of products.

The advantages of this method reveal a reduction in resources used and characterization time. As a result, the cost of a service is significantly lower than a conventional bench test.

For more information, contact our teams!