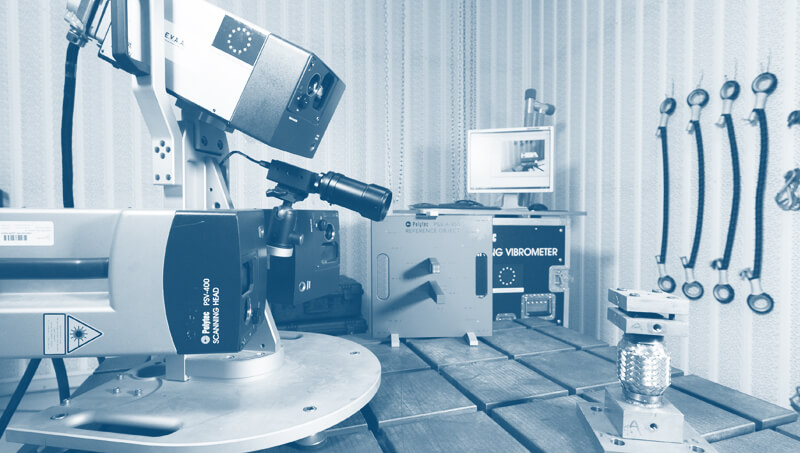

3D Laser Vibrometry measurements

CEVAA carries out different vibration characterizations with two 3D laser vibrometers, including an infrared one.

Vibration characterization by vibrometry

Advantages

- Measurement without contact, therefore non-intrusive

- High spatial resolution (number of pts / area units)

- Application on parts with high thermal stresses

- Use of mirror for simultaneous measurement of a front and rear face

- 3D measurement with optimized measurement time and possible automation (scanning system)

- Extended analysis domain (very wide frequency up to 80KHz)

- Automation of the measurement from a mesh taken from the video image of the object

- Possibility of using the finite element model of the simulation

- Mobile tool: packaging for transport to the customer site

Applications

- Experimental modal analysis (EMA) / Operational measurements of structure or subset (ODS)

- High frequency registration of finite element models

- Reliability of electronic boards / components

- Vibration analysis of electronic micro-components, MEMS – NEMS

- Study of the influence of damping materials on the vibro-acoustic behavior of structural elements

- Realization of strain mapping

On which parts? Which dimensions?

- Electronic micro-components

- Macro-structures (ex: engine, turbine, …)

Type of excitation?

- Measurement achievable under real excitation (operational measurements, ODS)

- Measurements achievable under artificial excitation (impact hammer, shakers) MIMO

The CEVAA has been using 3D laser vibrometry for several years. This experience makes our company a reference in the field.

Strong expertise in the aeronautics and space sectors but also in the automotive, railway, etc.

Advantage: we also travel to your site to carry out the measurements.

For more information, contact our teams!