Vibration analysis of rotating machines

CEVAA offers diagnostics and vibration analysis of rotating machines for industrial predictive maintenance.

What is vibration analysis of rotating machines?

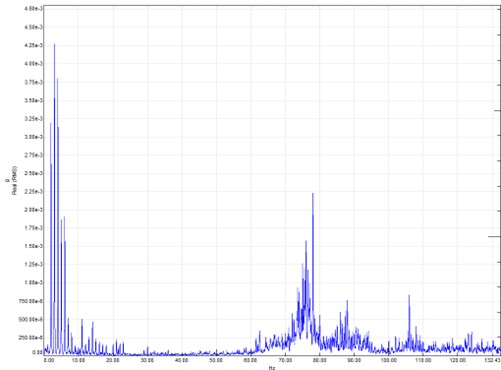

Vibration analysis is a non-invasive diagnostic method that assesses the health of a machine by measuring and analyzing the vibrations it emits. These vibrations, often imperceptible to the human ear, contain valuable information about the condition of the machine’s internal components and can reveal emerging defects long before they cause a breakdown.

Vibration analysis of rotating machines

CEVAA is your trusted partner in the field of vibrations. We provide you with in-depth expertise in vibration diagnostics and analysis. Thanks to cutting-edge tools and a team of qualified engineers, we help you optimize the maintenance of your rotating machines and prevent costly breakdowns.

With its expertise, CEVAA detects anomalies in rotating machines (gearboxes, motors, turbines, fans, pumps, shafts) before they become critical. Our teams participate in preventing breakdowns related to vibration problems.

Vibration analysis, a technique widely used in industry, offers continuous monitoring of equipment. In particular, it allows maintenance strategies to be adapted based on the results obtained. This non-intrusive method is now essential for optimizing the reliability and availability of equipment.

Engineering services by CEVAA

Vibration diagnosis of rotating machines

Our experts carry out vibration measurements on site and analyze the data collected to identify vibration sources and assess the health of the equipment.

Characterization of different types of defects

We carry out the analysis of the defect (imbalance, bearing defect, misalignment, etc.) and the evaluation of the severity.

Predictive maintenance and continuous vibration monitoring

We implement continuous vibration monitoring systems to allow you to follow the evolution of the condition of your equipment in real time.

What can vibration analysis control?

- Imbalance

- Misalignment

- Backlash

- Bearing defects

- Meshing

As soon as the vibration problem is taken into account upstream of production, it is possible to reduce premature wear of rotating machines. In this way, we can identify potential unwanted resonances and prevent the appearance of cracks.

Predictive maintenance of rotating machines

Avoid unplanned downtime and increase reliability!

By adopting a predictive maintenance approach based on vibration analysis, you benefit from many advantages:

- Equipment availability

- Cost reduction

- Improved safety

- Extended equipment life

- Reduced environmental impact

- Optimized production quality

For more information, contact our teams!