Squeak and Rattle Noise analysis

The study of noise is carried out by the CEVAA for manufacturers in order to understand acoustic phenomena and optimize systems.

What is interference noise ?

Interference noise is noise perceptible by customers, of a random nature, generated by external stresses (road profile, running on rails, jet engines, etc.).

Interference noise consists of sound emissions created:

- At the level of the contact surface of two parts during relative movements (squealing, grinding),

- By deformation of parts with unsuitable tolerances and coming into contact (crackling, rattling, etc.).

Acoustic tests and measurements

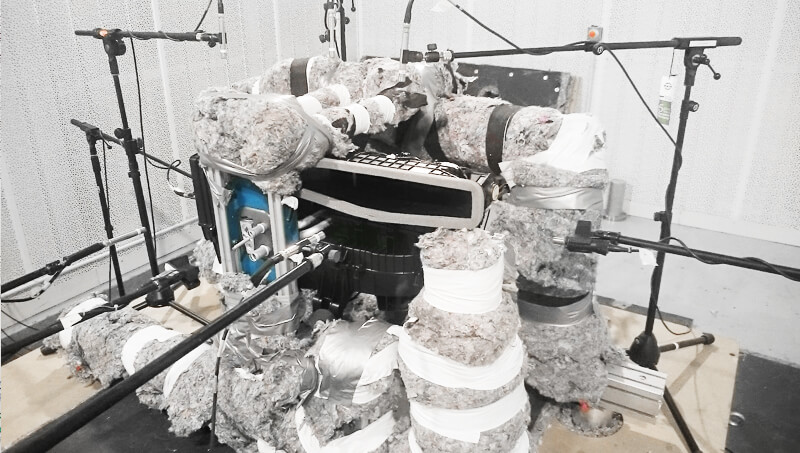

The test performed is noise detection on a bench, including (according to specifications), climatic + vibration ageing based on the following best practices:

- Background noise measurement

- Listening anew (subjective “human ear” listening) + rating of levels in dB(A) / sones

- Climatic and vibratory ageing

- Listening after ageing (subjective “human ear” listening) + rating of dB(A)/sones levels

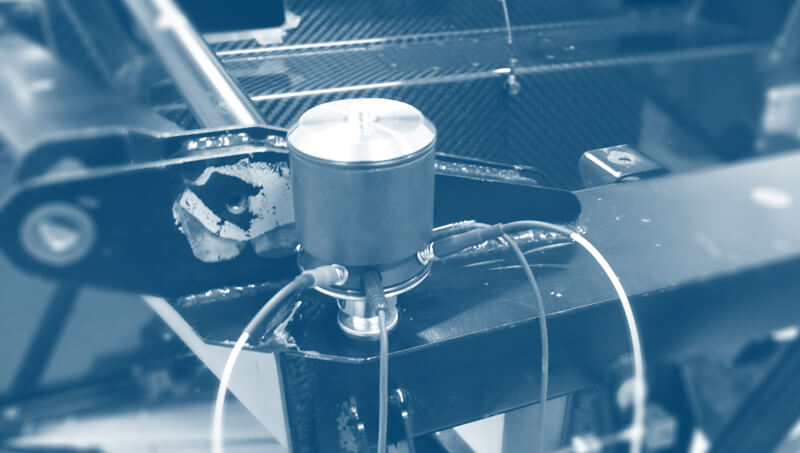

Measurement bench

The bench must have a background noise low enough to detect parasitic noise.

The measurements taken must be subject to a rating grid to classify the noise level of the product.

The CEVAA also has extensive experience in this area, particularly with equipment manufacturers in the Automotive sector:

- Trunk box with emergency inflation kit

- Tramway seats (with complete measurements taken directly on the system’s operating site for reproduction on a vibration bench)

- HVAC vehicles

Squeak & Rattle simulation

In addition to having this expertise, we offer our customers to take this subject into account upstream, during the product development phase.

Indeed, an additional skill “Squeak & Rattle simulation” makes it possible to detect potential problems with parasitic noise. An expertise that the CEVAA has mastered for several years with achievements in project mode for automotive manufacturers & suppliers, for the railway sector, etc.

For more information, contact our teams!