Shakers – vibrating pots

CEVAA offers its customers support in the understanding of vibration phenomena under vibration endurance tests.

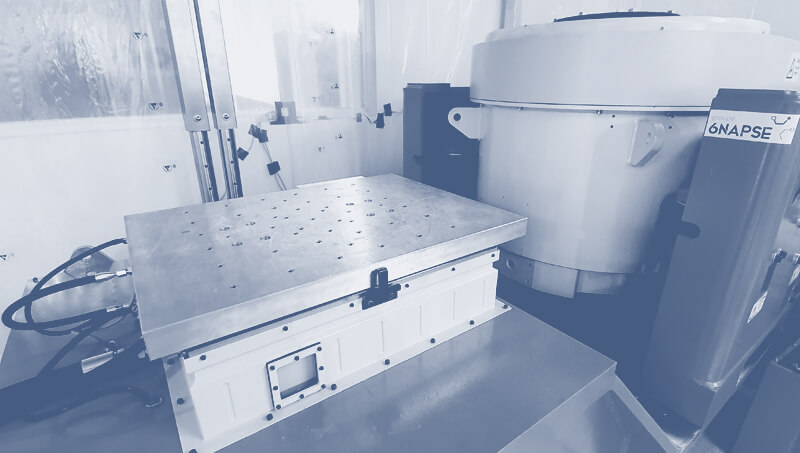

Shakers

At the 6NAPSE Group Test Center, we carry out vibration tests for the characterization or qualification of products according to specifications or standards (VITA 47; ISO 16750-3: 2012, etc.).

In addition, it is possible to combine these vibration tests with temperature cycles or under cleanliness class conditions.

En outre, il est possible de coupler ces essais vibratoires avec des cycles de températures ou dans des conditions de classe de propreté.

The CEVAA is called upon by a large number of sectors of activity to carry out tests on vibrators (Aeronautics, Space, Automotive, Rail, etc.).

In addition to this type of tests, the CEVAA is able to support its clients on related topics:

- 3d laser vibrometry measurements on product excited on vibrator

- Virtual vibration qualification tests before physical testing on a vibrating pot

- Customization of test (acceleration / severity of signals)

Power ranges

- 1kN: LDS V555

- 36kN: LDS V875LS – HBT600 table

- 60kN: LDS V8 – HBT600 table (ISO8 cleanliness class)

- 74kN: IMV A74 – VST900 table

- 89kN: LDS V964 – HBT1220 table (ISO8 cleanliness class)

- 125kN: IMV K125LS

ISO8 cleanliness class tents

Our vibrating pots are under laminar flow enclosure, allowing us to test in ISO8 cleanliness class (with lock to change, blouses, charlottes,…). In the tent, there are dedicated tools, dedicated sensors and cleaning equipment (isopropyl alcohol).

Methodologies

- Sinus strategy

- Random Strategy

- Shock Strategy, SRC Calculation

- Dwell Sinus Strategy

- Synthesis of SRC

- Time signal replication strategy

For more information, contact our teams!